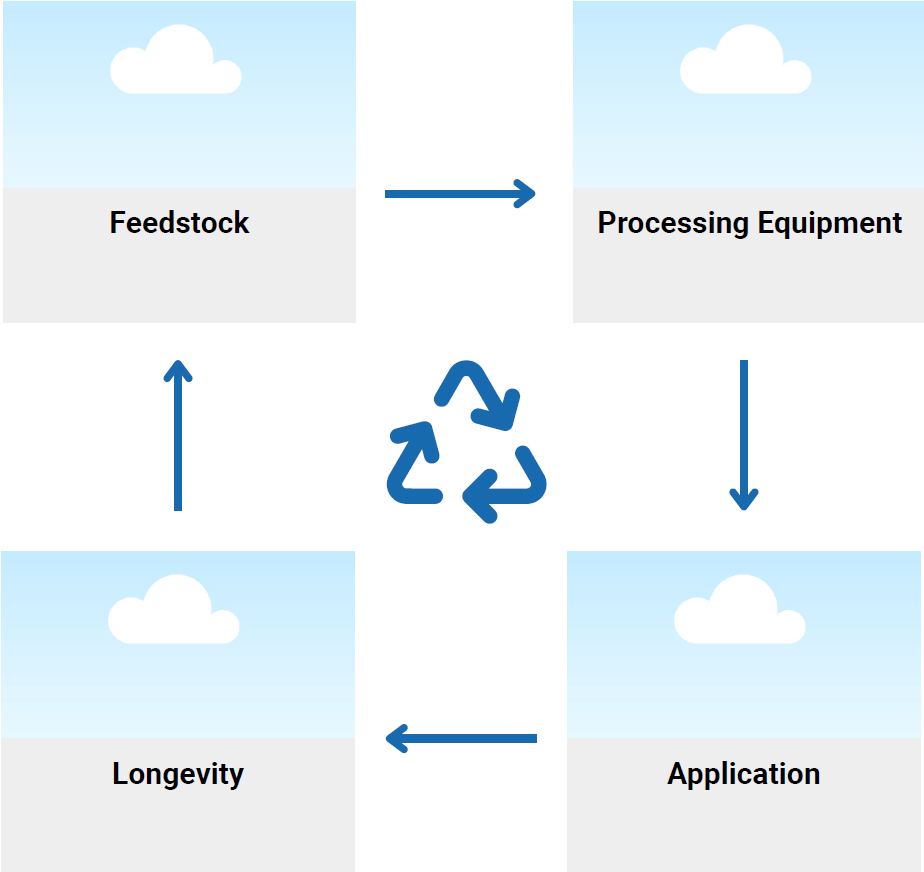

Every Product we make begins with a responsibility to reduce waste. By converting in-house trimmings and post-consumer recycled (PCR) milk packets into a valuable material, we keep resources in circulation and build products designed to last 15–20 years.

HOW WE CLOSE THE LOOP

Step-1

Collection

We systematically collect all production

trimmings and rejected components generated

during manufacturing. Instead of being

discarded, these clean, single-source materials

are segregated at the factory level, ensuring

traceability and consistent material quality. This

controlled collection forms the foundation of

our circular recycling workflow.

Step-2

Shredding

The collected plastic components are

processed in our in-house industrial shredder.

This step reduces larger pieces into uniform,

manageable fragments, improving material

consistency and enabling precise downstream

processing. Controlled shredding ensures the

material blends evenly while maintaining

predictable performance characteristics.

Step-3

Blending with PCR Material

Shredded production material is carefully

blended with post-consumer recycled (PCR)

milk packets. This measured blending process

allows us to responsibly incorporate recovered

consumer waste while maintaining structural

integrity. The result is a stable material mix that

reduces reliance on virgin inputs without

compromising product durability.

Step-4

Pulverising

The blended material is further processed in our

in-house pulveriser, where it is converted into a

fine, uniform black powder. Precise control over

particle size and consistency ensures reliable

melt behaviour during rotomoulding, enabling

smooth layer formation and consistent wall

thickness in the final product.

Step-5

Re-Moulding Into Long-Life Products

The recycled black powder is used to form the

inner structural layer of our planters through

rotomoulding. This layered construction

provides enhanced strength, impact resistance,

and dimensional stability while keeping recycled

material safely encapsulated within the product.

The result is a robust planter engineered for

demanding environments, with an expected

service life of 15–20 years.

Measurable Impact, Built Into Our Process

Every recycled decision translates into real, trackable outcomes.

13 TONS*

Post Consumer Waste Recycled so far

34 TONS*

Pre Industrial Waste Recycled so far.

3.35 MILLION*

Milk pouches saved from reaching landfills

Measured today. Built to grow. Our recycling efforts translate into real impact, integrated directly into how we make our products..

Behind every recycled material is a team ensuring it’s done right.

Coming Soon